Hi there readers! I hope this post finds you safe and well (or at least distracts you from your troubles for a while). This post focuses on my method for making Bronze Age armour scales, using vegetable tanned leather. They're very easy, and it's not hard to adapt the techniques to produce other kinds of scales. Whether you're into historical reenactment, cosplay, LARPing, or whatever else you're doing that requires scale armour, I want to show how easy it is to make yourself with very minimal equipment. It's stress relieving too, because you get to hit things with a hammer.

Bronze Age armour scales nearly always had a distinctive longitudinal ridge which gives the scales their characteristic cupped shape and helps them curve around the body effectively. To get this curve, all you have to do is soften the leather in hot water and hammer it into a mould.

You need:

- Narrow-bladed knife to punch holes - something like an Xacto knife works well

- Hammer

- Blunt table knife

- Block of wood with a groove cut into it

- Scale shapes cut out of vegetable tanned leather using either a knife or leather shears

I do recommend investing in a pair of leather shears, which are not too expensive and will make the job so much faster and easier. Vegetable tanned leather is tough stuff, and depending on how thick it is you won't be able to cut it with regular scissors.

To shape the scales, soak them in hot, but not boiling, water until they become soft and pliable, then use your blunt knife and a hammer to push them into the groove you carved in your block of wood. Thicker scales will need to be hammered quite hard, thinner ones not so much. You'll soon get a feel for how much force needs to be applied. It's best to soak and hammer scales in batches of ten or so, because as the water cools the scales will become less pliable.

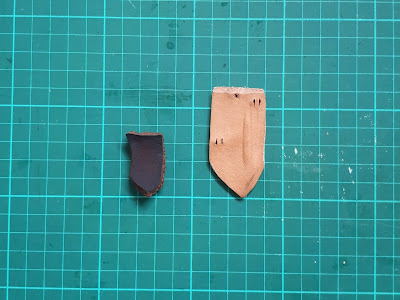

Why should you not use boiling water? Let me demonstrate:

These scales started out identical, but the one on the left was dunked in boiling water. It only takes seconds for vegetable tanned leather to turn into a tiny, hard lump in boiling water. The end result is very tough, but can't be shaped or perforated. You want water that is too hot to put your hand in, but not actually boiling. When the water is cool enough to put your hand in and air bubbles have stopped coming out of the scales, they should be good to go.

Thicker scales can be left to air dry after shaping, but for thinner ones I recommend baking them on metal cookie trays for 5 to 10 minutes at around 80 degrees Celsius. It hardens the leather slightly. I don't know if the ancient Egyptians baked their scales, but I suspect they could have achieved a similar result by placing their scales on a metal sheet in the sun. Unfortunately the sun here isn't hot enough to test it. Be very careful when baking scales or they will turn into blackened little lumps like they do if you boil them. Check them every few minutes and take them out as soon as the undersides start to become a darker colour. They won't be completely dry at this point; the baking process isn't to dry them out, it's to toughen them by altering the leather's protein structure.

Once your scales are dry it's time to punch lacing holes. How many holes, and where, is dependent on how you're going to lace them; these ones are going to be a replica of Tutankhamun’s chariot armour so the holes are situated in the same places as the holes in Tutankhamun’s scales. Bronze Age armour scales could be laced together in a variety of ways, and for a better understanding of how the process worked I recommend checking out Dr. Hulit's thesis Late Bronze Age Scale Armour in the Near East: An Experimental Investigation of Materials, Construction, and Effectiveness, with a Consideration of Socio-economic Implications, available free from the e-theses online service. I plan to discuss the details of how I lace these things together in a future post. The easiest way to punch lacing holes is with the point of a knife, after the scales are shaped and dried. Whoever made Tutankhamun’s armour used a knife too, presumably for the same reason. You'd think a hole punch should make this job easier, but in my experience it doesn't.

To reduce costs, you can make at least some of your scales out of belly leather. Tutankhamun's scales ranged from 1.8mm to 2.5mm in thickness, so belly leather is often too thick for the smaller scales, but it should be fine for the larger, thicker ones used in the skirt section. Just keep an eye on the grain. Grain can be a bit weird on belly leather and you need to cut all your scales with the grain running lengthwise. You don't need the highest grade of leather either; cheaper stuff is fine as long as it's an appropriate thickness. Because the scales are small they can be made from odd sized offcuts with very little wastage, which is helpful, because you're going to need around 2000 for a full length cuirass and that means 40 to 50 square feet of leather.

Very interesting article! I've heard of cuir boulli, of course--what you get by boiling leather, which has been used as armor at times. But I did not realize that dunking leather in somewhat less than boiling water can also have a useful result. Thank for that piece of knowledge.

ReplyDeleteYou're very welcome! I kind of doubt whether cuir boulli was really boiled as such, given the results I got when I boiled that scale, but I haven't researched it in any depth. Perhaps different tanning processes yield different results during boiling.

DeleteThat's possible; I haven't explored leather working of any kind in depth, so I can't say.

DeleteThis is such a detailed and well-written guide! I’ve been looking for a beginner-friendly way to make scale armour. Thank you for sharing your expertise.

ReplyDeletefranchise Expo

franchise Expo Mumbai

The step-by-step explanation is fantastic! I can’t wait to try this for my next LARP event.

ReplyDeletefranchise Expo Bangaluru

Trough Screw Conveyor delhi

Wow, I never knew you could shape leather like this! The tip about not using boiling water is a lifesaver.

ReplyDeleteAutomatic Bag Slitting Machine

Micro feed screw delhi

This post is gold! Do you have a recommendation for a good brand of vegetable-tanned leather for beginners?

ReplyDeleteWarehouse Storage rack

mezzanine floor

I love the historical context you included about Tutankhamun's armour. It really brings the process to life!

ReplyDeletemobile compactor in delhi

fifo flow rack manufacturer

I’m amazed at how resourceful this method is. Making scales out of offcuts is such a smart way to save costs.

ReplyDeleteheavy duty rack delhi

Multi tier rack delhi

I’ve always wondered how Bronze Age armour was made. This hands-on guide makes it seem so approachable. Thanks!

ReplyDeleteSlotted Angle rack delhii

Pallet rack manufacturer

This is perfect for my next cosplay project. Do you think painting the scales after shaping them would work?

ReplyDeleteDust Collector

Franchise Opportunities

This guide is incredibly helpful. I’ve been struggling to find accurate tutorials for Bronze Age armour. Keep up the great work!

ReplyDeleteFranchise India Expo

Franchise India Expo Mumbai

The baking tip is genius! I’ve been air drying mine, but they always felt too soft. Can’t wait to try this.

ReplyDeleteFranchise India Expo Bangaluru

Trough Screw Conveyor feeder delhi

The groove in the wood block for shaping scales is such a clever idea. I’m definitely stealing that hack!

ReplyDeleteSilo Top Dust Filter in delhi

vibro sifter delhi

Your explanation of the difference between boiling and hot water was so clear. Saved me from ruining a batch of leather.

ReplyDeleteWarehouse Storage rack manufacturer

mezzanine floor manufacturer

I can’t believe how simple this process is! I’ve always thought making armour was super complicated.

ReplyDeletemobile compactor Manufacturer

fifo flow rack

How long does it take to make enough scales for a full cuirass? I’m curious about the time commitment.

ReplyDeleteslotted Angle rack manufacturer delhii

pallet rack in delhi

The section on grain alignment was super insightful. It’s these little details that make such a big difference!

ReplyDeleteDust collector manufacturer

Franchise for sale

I appreciate the link to Dr. Hulit’s thesis. It’s rare to find historical accuracy paired with DIY tutorials.

ReplyDeleteFranchise Show

Franchise Show Mumbai

Would you recommend a specific type of knife for punching holes? My Xacto blade keeps slipping.

ReplyDeleteFranchise Show Bangaluru

Tubular Screw Conveyor delhi

This guide is an absolute gem. The mix of crafting tips and historical insights makes it a pleasure to read.

ReplyDeleteLoss in weight Feeder delhi

pneumatic vibrator delhi