Saturday was brew day at my house. I made some farmhouse ale like great-times-many grandma used to make. Farmhouse ale is also known as raw ale, and the defining characteristic is that it's made without boiling the wort. This is how most beer was made up until recently, because in the past people didn't have access to metal containers large enough to boil their wort.

As an aside, you may have noticed there's no airlock on that container. When I made mead I found I didn't really need one. The container's cap is screwed in place loosely, which allows the carbon dioxide to escape and prevents contaminants from getting in. That's what an airlock does, plus it lets the brewer see whether fermentation is taking place. I know whether fermentation is taking place because I can hear it bubbling when I put my ear next to the cap.

Anyway, back to the ale. I discovered the concept of raw ale when I found Lars Marius' excellent blog, and decided I would like to try some. Apparently it is very different to beer made with boiled wort, but in a good way. This seems to be because the protein from the barley, which is normally destroyed by boiling, remains in the beer. Farmhouse ale, therefore, is a source of protein and more nutritious than your typical modern ale. The downside is that leaving the protein in the beer reduces its shelf life, but if it tastes good this will not be a problem.

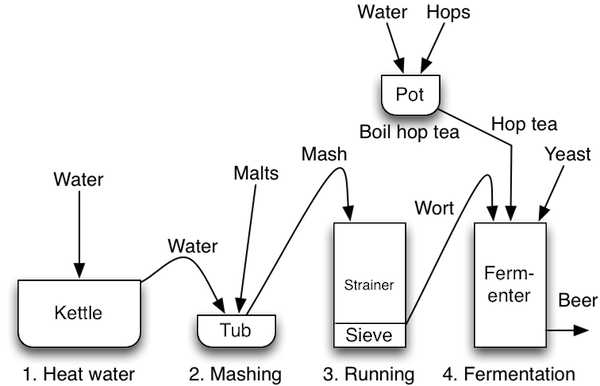

The process for making farmhouse ale is a fairly simple one, as summarized in the following diagram:

I used a simple infusion mash - I just added hot water to crushed grain, and left it for 90 minutes with towels wrapped around the pot to keep the temperature stable (thanks to Chris Colby at Brew Your Own for that helpful suggestion). My hops were boiled for 60 minutes.

The amount of grain per liter of recipe yield seems to vary a lot, but based on things I've read online I've assumed between 0.25 to 0.6 kilos of grain per liter of beer. I've got about 9 liters of beer using 3 kilos of grain. Here are the ingredients I used:

Things I have learned so far:

But will my ale be any good? I have no idea and will just have to wait and see. What I do know is that at $15.80 for 9 liters, if this is even vaguely drinkable it will be good value for money. It's just about finished its primary fermentation now, and so far its colour and smell are not unlike Funk Estate's Berliner Weisse. Hopefully that's an indication of the flavour.

|

| My first ever batch of farmhouse ale |

As an aside, you may have noticed there's no airlock on that container. When I made mead I found I didn't really need one. The container's cap is screwed in place loosely, which allows the carbon dioxide to escape and prevents contaminants from getting in. That's what an airlock does, plus it lets the brewer see whether fermentation is taking place. I know whether fermentation is taking place because I can hear it bubbling when I put my ear next to the cap.

Anyway, back to the ale. I discovered the concept of raw ale when I found Lars Marius' excellent blog, and decided I would like to try some. Apparently it is very different to beer made with boiled wort, but in a good way. This seems to be because the protein from the barley, which is normally destroyed by boiling, remains in the beer. Farmhouse ale, therefore, is a source of protein and more nutritious than your typical modern ale. The downside is that leaving the protein in the beer reduces its shelf life, but if it tastes good this will not be a problem.

The process for making farmhouse ale is a fairly simple one, as summarized in the following diagram:

|

| Diagram from Larsblog |

I used a simple infusion mash - I just added hot water to crushed grain, and left it for 90 minutes with towels wrapped around the pot to keep the temperature stable (thanks to Chris Colby at Brew Your Own for that helpful suggestion). My hops were boiled for 60 minutes.

The amount of grain per liter of recipe yield seems to vary a lot, but based on things I've read online I've assumed between 0.25 to 0.6 kilos of grain per liter of beer. I've got about 9 liters of beer using 3 kilos of grain. Here are the ingredients I used:

- 3 kilos of mild ale malt

- Half a pack of Styrian Goldings hop pellets

- Half a pack of Mangrove Jack brand Belgian ale yeast

- A pinch of coriander seeds. I like coriander in my beer.

Things I have learned so far:

- Brewers' World in Lower Hutt is awesome.

- I need a bigger mashing receptacle. Anyone got a chilly bin or boil-up pot they don't want anymore?

- According to some of the posts on Larsblog raw ale can be an acquired taste, and I can believe that. It looks like the ale will be quite thick and have a lot of body to it, which doesn't really surprise me given its protein content, and if you normally drink commercially produced lagers this stuff probably would be very different from what you're used to.

- Hop pellets totally look like a pot of boiling pond scum when they are being cooked.

|

| See what I mean? |

But will my ale be any good? I have no idea and will just have to wait and see. What I do know is that at $15.80 for 9 liters, if this is even vaguely drinkable it will be good value for money. It's just about finished its primary fermentation now, and so far its colour and smell are not unlike Funk Estate's Berliner Weisse. Hopefully that's an indication of the flavour.

I don't drink alcohol, partly for medical reasons, and I've never liked beer much, but I wish I could taste your finished product! Good luck with it.

ReplyDeleteThanks! I hope it's good, but either way it will be a learning experience. When it's ready to drink I'll write a blog post with description/tasting notes, so you'll know what it is like.

DeleteI'm looking forward to that post!

DeleteI'm looking forward to that post!

Delete